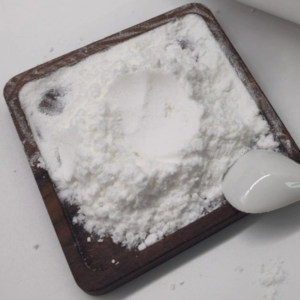

Sodium silicate, also known as water glass or liquid glass, is a compound derived from sodium oxide (Na2O) and silicon dioxide (SiO2). It is typically produced by melting a mixture of sodium carbonate (soda ash) and silica sand, followed by rapid cooling to form a solid glassy material.

Sodium silicate is available in various forms, including solid powders, granules, and liquid solutions, and it has a wide range of industrial applications:

- Adhesives and Binders: Sodium silicate is used as a binder in the manufacture of various materials, including cardboard, paper, and briquettes. It acts as a binding agent that solidifies when exposed to carbon dioxide, providing strength and stability to the finished product.

- Detergents and Soaps: In detergents and soaps, sodium silicate is used as a corrosion inhibitor and a builder. It helps to soften water by sequestering metal ions, preventing the formation of scale and improving the cleaning efficiency of the detergent.

- Water Treatment: Sodium silicate is utilized in water treatment processes, particularly for the coagulation and flocculation of suspended particles. It helps to aggregate and settle impurities in water, facilitating their removal and purification.

- Construction: Sodium silicate is used in the construction industry as a concrete sealer and surface hardener. It can penetrate concrete surfaces, filling pores and voids, and forming a durable protective layer that enhances resistance to moisture and chemicals.

- Fireproofing: Sodium silicate is employed as a fireproofing agent in various applications, including the treatment of fabrics, wood, and paper. When applied, it forms a protective barrier that inhibits the spread of flames and reduces the combustibility of the material.

- Chemical Manufacturing: Sodium silicate serves as a precursor for the production of other chemicals, such as silica gel, zeolites, and silica nanoparticles. It is also used as a catalyst or reagent in certain chemical reactions.

Reviews

There are no reviews yet.