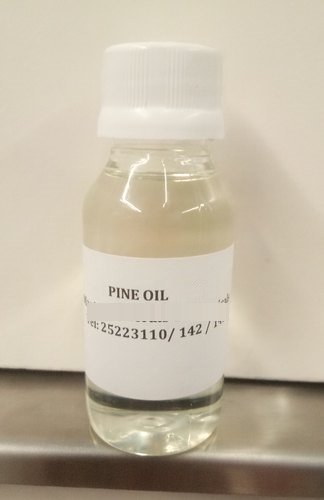

Pine oil, typically containing 39% to 49% pine oil as its active ingredient, is a natural frother commonly used in mineral processing, particularly in the flotation of sulfide ores.

- Function: Pine oil serves as a frother in the flotation process, aiding in the formation and stabilization of froth on the surface of the flotation cell. This froth layer assists in the selective attachment of valuable minerals to air bubbles, facilitating their recovery from the ore slurry.

- Composition: Pine oil is derived from pine trees and contains various terpene compounds, primarily consisting of alpha-terpineol, beta-terpineol, and other hydrocarbons. The concentration of pine oil in the product typically ranges from 39% to 49%, with the remaining content comprising other substances and solvents.

- Application: Pine oil is widely used in the flotation of sulfide minerals, such as those containing copper, lead, zinc, and nickel. It is known for its ability to produce a stable froth with good air dispersion, enhancing the efficiency and selectivity of the flotation process.

- Characteristics: Pine oil exhibits excellent frothing properties due to its hydrophobic nature, which helps create a froth layer that can selectively adhere to the surfaces of valuable minerals, making them floatable. It also contributes to the control of bubble size and mobility in the flotation cell.

- Usage: Pine oil is typically added to the flotation circuit in the appropriate dosage to achieve the desired frothing effect. The dosage may vary depending on factors such as ore type, particle size, pH, and other process parameters.

Overall, pine oil is a widely used frother in mineral processing due to its natural origin, effectiveness, and relatively low cost. It plays a crucial role in the separation and recovery of valuable minerals from ore slurries during the flotation process.

Reviews

There are no reviews yet.