Ethyl thiocarbamate, also known as sodium diethyl dithiocarbamate, is a chemical compound primarily utilized in the mining industry, particularly in the flotation process for the separation of minerals.

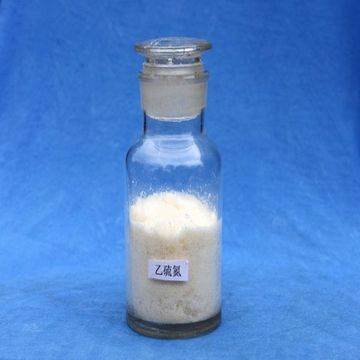

Composition: Ethyl thiocarbamate is a dithiocarbamate compound, with the molecular formula (C2H5)2NCS2. Sodium diethyl dithiocarbamate is its sodium salt form. The designation “≥ 94%” indicates that the purity of the compound is at least 94%, with the rest comprising other compounds or impurities.

Function: Ethyl thiocarbamate acts as a collector in mineral flotation. In the flotation process, it selectively attaches to the surface of desired minerals, making them hydrophobic and facilitating their attachment to air bubbles. This aids in the separation of valuable minerals from gangue minerals in the flotation cell.

Application: Ethyl thiocarbamate is commonly used in the flotation of sulfide minerals, such as those containing copper, lead, zinc, and nickel. It plays a crucial role in enhancing the efficiency and selectivity of the flotation process by promoting the flotation of desired minerals while minimizing the flotation of unwanted minerals.

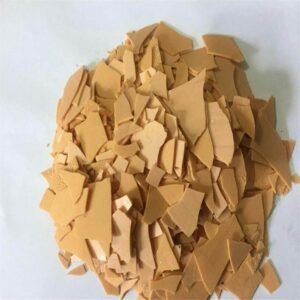

Characteristics: Ethyl thiocarbamate exhibits excellent flotation properties due to its ability to form stable complexes with metal ions on mineral surfaces. Its effectiveness in mineral flotation is influenced by factors such as pH, pulp density, and the presence of other chemicals in the flotation process.

Usage: Ethyl thiocarbamate is typically added to the flotation circuit in the appropriate dosage to achieve the desired flotation effect. The dosage may vary depending on factors such as ore type, particle size, and the specific requirements of the flotation process.

Overall, ethyl thiocarbamate plays a crucial role in mineral processing operations by aiding in the efficient separation and concentration of valuable minerals from ore slurries during the flotation process.

Reviews

There are no reviews yet.